본 장비는 소량 다품종 생산에 적합한 장비이다. Solder Printer에서 제일 중요한 작업은 Squeegee이며, 반복적 작업에도 균일한 품질이 가능한 Double Squeegee가 가능한 장비이며 , 양면 PCB 작업이 가능한 Solder Printer 입니다.

균일한 프린팅 품질 구현이 가능한 장비이다. X.Y.D측 세밀조정이 가능하며 4면체의 높이 조절이 가능 합니다.

Double Squeegee, 양면 Printing이 가능하며, Table 면은 X.Y 측 고정 탭 홀이 있어 어떠한 제품의 고정이 가능 합니다.

적용공정 : Small Multi Product / 연구소 / 부품소재 / 품질관리 / 정밀을 요구하는 소량 다품종 업종에 적합.

Product Description:

Raise the template, take out PCB board, finish printing pad on it.

the scraper moving of automatic printing is drive by parallel guideway with screw drive, using screw rotate to finish scraper moving rubber scraper is used in manual printer.

Speed, angle and pressure are controlled by operators. with the rapid development of the electronics industry, the integration of emerging chip increase, the accuracy of the printer made great challenges, especially for small manual printer, some problems are below.

1

|

The worktable can’t meet high precision printing

|

2

|

Manual speed, angle and pressure are not controlled very well.

|

3

|

Printing consistency is a problem. Manual printer T1000 resolve above problems. Now, T1000 has applied patent

|

M3545 is similar function with automatic printers with low cost. It reduce cost and improve efficiency

Include:

2. 8 x PCB 휨 방지 Support Pin

3. 2 x 200mm Metal Squeegee

4. 1 x 육각 렌지 Driver

5. 1 x 사용자 Manual

▲ Max print area:280 x 320mm (opt)

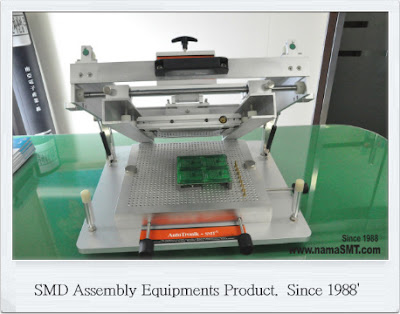

장비. 사진으로 설명

반복적인 고정밀 프린팅 작업 적합 Printer.

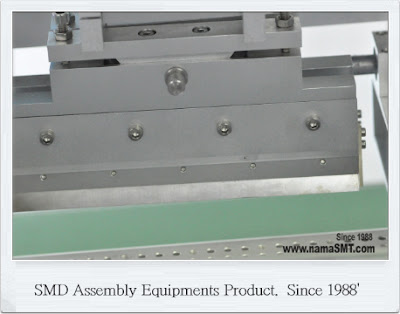

Ball Screw 방식으로 흔들림이 없음

Handle 로 Double Squeegee 자동 변환

2 x Metal Squeegee 200mm 기본 제공

다양한 유형의 Printer 작업물 고정 가능

X.Y측 Hole 및 Screw Tab이 있음

운영이 간편하고 반복적 작업에 정밀도가 우수하다.

PCB 교체 작업 시 Stencil frame unit 올린상태

다양한 Frame 고정 가능

Frame 폭 좌/우 조절을 하는 기능이 있다

작은 Frame 사용 사례

Universal PCB Fixture Double Printing 가능

Table 밑면에 타공된 Hole Screw tab 있으며,

홀에 Universal Fixture를 이용하여 다양한 Printer 소재를 고정 할 수 있다.

Screw 탭 가공이 되어 있으므로 고정 가능

PCB 고정 Pin 및 Hole Pin 높이 조절가능

PCB 두께에 따라 조절 가능

어떠한 면체에서 공정 가능

양면 PCB 고정 사례

오일 쇼바가 있어 어떠한 작업 위치에서 정지 가능

손쉬운 Frame 고정 . 두께에 제약이 없음

후면 2개의 Stencil 두께에 따라 높이 조절

매우 작은 Stencil 적용사례

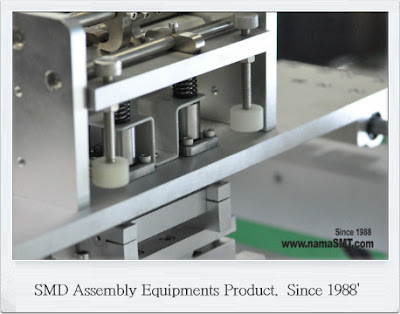

Top Cover을 제거하면 Squeegee 좌/우 높이 조절 가능

Squeegee Z측 좌/우 높이 조절 기능

좌/우 대칭. Squeegee 높이 조절을 할 수 있다

Squeegee 조절 Double Side

양쪽 흰 우래탄은 완충기능이며 좌/우 Squeegee 높이 조절한다

측면 Screw 4개 풀으면 된다

Squeegee 이동 측 거리 Stopper

작은 PCB 작업을 때, 효율적이다.

전면 X측 혹은 D측 조절이 가능

조절이 끝나면 조립하는 상태

유자보수가 매우 간편하다.

Stencil Frame 높이 조절 . Stopper 우측

다양한 PCB. 소재 Fixture 가능한 work Table.

SPEC M3545

| ||

1

|

Scraper width

|

200mm,280mm(op), Fame Max 490 x 420mm

|

2

|

Squeegee

|

200mm [Standard] , . Max 280mm (option)

|

3

|

Scraper angle

|

60' ( squeegee 각도 )

|

4

|

Scraper material

|

stainless steel(other material can be ordered)

|

5

|

Adjusting accuracy

|

0.01mm

|

6

|

Repeat accuracy

|

0.03mm

|

7

|

0.4mm IC

|

0.4mm IC

|

8

|

Expected printing speed

|

60 – 100 pcs/h

|

9

|

Accessories

|

1. 8 x Thimbles

|

2. 6 x support shelves

| ||

3. 1 x Inner hexangular spanner

| ||

4. 6 x Nuts and Bolts

| ||

Technique parameter: Introduction

screen printing machine is common equipment in SMT industry, printing process

Include:

1. put and fix PCB(Printed circuit board) at the bottom of moulding board;

2. put solder paste into inside the template scraper is moved by drive device,

solder paste is printed on the PCB through the bore on the template.

3. Raise the template, take out PCB board, finish printing pad on it. the scraper moving

of automatic printing is drive by parallel guideway with screw drive, using screw

rotate to finish scraper moving; rubber scraper is used in manual printer.

Speed, angle and pressure are controlled by operators. with the rapid development of

the electronics industry, the integration of emerging chip increase, the accuracy of the

printer made great challenges, especially for small manual printer, some problems are below:

1 .the worktable can’t meet high precision printing;

2 .manual speed, angle and pressure are not controlled very well;

3. printing consistency is a problem. Manual printer M3545 resolve above problems.

Now, M3545 has applied patent in China. M3545 is similar function with automatic printers with low cost. It reduce cost and improve efficiency.

M3545 principle and technology parameters

▲ M3545 is manual high precision screen printing machine, without electric components

and air components(air handspike)

▲ Scraper moving is driven by precision guideway to make no space touch between

scraper and moulding board.

▲ Using magnetism thimble and omnipotent thimble to position and support PCB to

make sure take off template.

▲ Install template with double side fixing technology.

▲ with two scrapers design. The pressure adjustment is by mechanism adjusted,

mechanism insurance control ascend and descend of scraper.

▲ Round axes guideway can be adjusted by fix frame. All kinds of moulding board can

be installed on printers.

▲ lifting template can be finished by handle, using it with air handspike.

▲ X,Y,Z and angle can be adjusted, adjusting 4 axes to achieve corresponding between

pad and bore, adjust distance between PCB and moulding board by platform.

▲ Fix scraper and run it on the parallel guideway, there are front scraper and back

scraper. They can ascend and descend, after step 1, front(back) scraper fall down

printing location, and then run backward(frontward), after running, scrapers go back

original station.

▲ Max print area:280 x 320mm (opt)

Option

1) Squeegee 300mm

2) Vacuum Block

3) 교반기