본 장비는 full Automatic Stencil Printer로서 독일의 Autotronik-SMT GmbH 회사에서 개발하여 판매되는 장비 입니다. 장비의 정밀도. 내구성이 뛰어나며, 반복작업에 우수한 균일한 작업 구현이 가능한 장비 입니다.

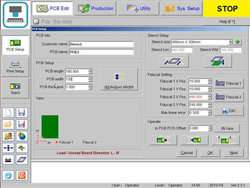

Software의 단순 정밀 구조로 되어 있어 어떠한 작업자도 빠르고 쉽게 고품질 작업 구현이 가능 한 장비 입니다.

고객의 작업 Size에 맞게 확장을 할 수 있으며,Squeegee위 높이을 압력 센서에 의한 Stepping Motor제어로 z측을 제어 합니다.

본 장비는 미국의 Manncorp에서 연간 200 System 이상 판매하여 내구성을 인정 받은 장비 입니다.

Fully Automatic Stencil Printer

1. 430 is a high-precision, fully automatic SMT stencil printer with a print area up to 400 x 350 mm

optional : 450 x 350 mm . 736 mm x 736 mm.

2. High quality prints are guaranteed with the printer’s 4-point ball screw drive and programmable speed control for both the blades and stencil-PCB separation. Fast PCB alignment is achieved with the system’s dual-camera system. Gain Access to Prices, Quotes and Buying Online

3. Precise height adjustment of PCB holding table using ball-screw driven control. Accurate vertical adjustments of stencil frame driven by ball-screw in fast and quiet movements.

4. Full Automatic stencil cleaning device included for ease of use and continuous production.

5. Advanced imaging system allows wide selection of fudicial mark terns on stencil. No specialized fudicial mark on stencil is required. lignment of stencil on PCB board can easily be achieved for the best printing result.

6. with simultaneous control of all axis movements, machine can uickly restore to home position for quick restart of next printing task.

Machine parameter set up is easy so that changeover between different production lines is simple and fast. Multiple light source selection feature helps easy handling of different colored PCB when learning fudicial reference points.

7. Multiple user permission levels available, avoid important machine parameters to be accidentally changed due to human error.

Fast, easy job changeover

AP430, which accommodates stencils from 420 x 420 mm to 736 x 736 mm, makes job set up simple: input the stencil size, insert the stencil into the frame mounter until it reaches the stopper, and the system software will handle the rest. Be ready for the next production assignment in a matter of seconds.

Windows-based AP430 is easy to program, allowing the printer to be up and running quickly after install. All parameters, including print speed (programmable from 20 to 120 mm/s), stroke length, squeegee pressure, etc., are fully programmable via the graphical user interface. During operation, all details, including process status, of the current job are displayed on screen.

Dual, independent print heads increase throughput

AP430’s two print heads are independently controlled by high-precision ball-screw drives with a programmable transport speed. Print pressure is uniformly and accurately controlled. Self-leveling squeegees automatically adjust to the stencil surface to ensure perfect registration on every print.

SMEMA-compatible for inline integration EU Version

The efficient single-stage PCB transport system is SMEMA-compatible to interface with the other production equipment on your line.

Integrated understencil wiping

Automatic wet/dry/vacuum understencil cleaning is included with the AP430. The system can be programmed to clean the stencil using any combination of dry wipe, wipe with solvent (“wet wiping”), or wipe followed by vacuum to draw material out from the apertures.

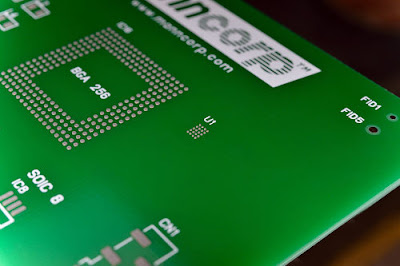

고 밀도 High pitch 작업에 우수한 품질 구현

BGA. UBGA. Flat chip 작업 품질도 우수함.

01005에도 우수한 프린팅 가능 합니다.

.jpg)